1.Product Introduction

(PDLC) EVA film(0.8mm) for Smart glass it’s specially used for intelligent glass(bonding the liquid crystal film and glass firmly together)

Four major advantages:

- High light transmittance (light transmittance can reach 93%), showing perfect visual effect.

- Super strong bonding strength, safety is guaranteed.

- Perfect weather resistance, ensuring the service life of smart glass.

- The stability of the dimension solves the displacement problem of intermediate materials and improves the yield.

| Product name | Thickness(mm) | Width(mm) | Length(m) | Scope of application |

| EVA film for dimming film | 0.6 | ≤2700 | 50 | Application: dimming glass (liquid crystal glass, atomized glass, electrified glass) and LED light-emitting glass laminated glass. |

| 0.66 | ≤2700 | 50 |

| 0.76 | ≤2700 | 50 |

| 0.8 | ≤2700 | 50 |

2.Product detailed parameters

| 项目 Item | 单位Unit | 性能指标 Performance Index |

| 熔点 Melting Point | ℃ | 64 |

| 密度 Density | g / cm³ | 0.988 |

| 玻璃化温度 Glass Transition Temp | ℃ | -40 |

| 拉伸强度 Tensile Strength | Mpa | 18.75 |

| 断裂伸长率 Elongation (before laminated) | % | 755 |

| 吸水率 Water absorption | % | <=0.18 |

| 雾度 Haze | % | 0.12 |

| 透光率 Light Transmittance | % | 94.1 |

| 粘结强度(玻璃) Bonding Strength (glass) | N / 10mm | 138 |

| 紫外线阻隔率 UV reduction | % | >=98.8 |

| 耐紫外线老化 UV aging resistance (15Kwh / m2、290~385nm) | 透光率%Light Transmittance% | 92.2 |

| 耐湿热老化 Heat aging resistance ( 85℃85%湿度humidity1500h) | 透光率%Light Transmittance% | 91.7 |

| 散弹袋冲击性能 Impact resistance against shot-bag GB-15763.3-2009 | 1200MM | 两面玻璃破裂,无穿透性开口 Qualified |

| 落球冲击试验 Ball impact resistance GB-15763.3-2009 | 4800MM | 胶层未断裂、未暴露 Qualified |

| 耐湿性 Humidity aging resistance GB-15763.3-2009 | | 未产生气泡或其他缺陷Qualified |

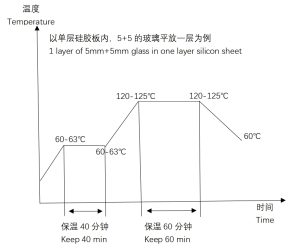

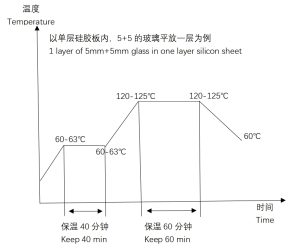

3.Processing Technic

Note:

1.After combining the glass, it must be wrapped around by high temperature tape(don’t worry about the exhaust).

2. Cold draw for 10 minutes, based on the temperature of the glass surface

2.Please delay the keeping time if the laminated glass thickness increased or SQM increased.

4.Application Cases

5.Packaging and transportation

6.Save method

1) EVA laminated glass adhesive film is usually required to be stored in a ventilated, dry, and clean warehouse, avoiding direct radiation from light and heat sources; Prevent rain, heavy pressure, external impact, and scratches from hard objects; The temperature in the warehouse should not exceed 30 ℃, and the humidity should not exceed 60%; When there is a large inventory of film, a tray should be placed under the film to facilitate ventilation, heat dissipation, and moisture isolation. If the film is subjected to pressure, heat, or excessive moisture, it may exhibit varying degrees of self adhesion. If possible, please hang it for storage and avoid heavy pressure as much as possible. If the surface humidity of the adhesive film is too high, it will also affect the bonding strength between the adhesive film and glass or other adhesives, affecting normal use.

2)EVA laminated glass film is prohibited from being stored in the same warehouse as flammable and explosive materials; The remaining film after use must be repackaged with clean materials to prevent the weak static electricity carried by the film itself from adsorbing dust and contaminating the film, affecting normal use.

3) EVA laminated glass film has an “effective storage period” of ten months from its production. Customers with inventory turnover must perform a rolling operation of “storing new and using old”. If customers use film that has exceeded the storage period for production and processing, we are not responsible for the quality of their products. If the film purchased by the customer has not been used for a long time and the storage period has exceeded the “effective storage period”, regardless of whether there are inherent quality problems with the product, we will not process returns or exchanges.

7.Special Warning

Whether it is EVA film or intermediate materials (such as photo paper), due to improper storage, there will be “discharge” phenomenon in rainy and humid weather. Even if glass appears, there will still be a thin layer of water mist floating on the surface of the glass. If this “moisture” phenomenon is not ruled out, the bonding strength of tempered glass after processing and forming will be greatly affected. Therefore, customers are advised to avoid high humidity weather during production. Proper drying of materials and glass is beneficial for improving bonding strength.